Termite Reticulation System

Termite Reticulation System

Trust the Experience

Termite Reticulation (Termite Piping) System

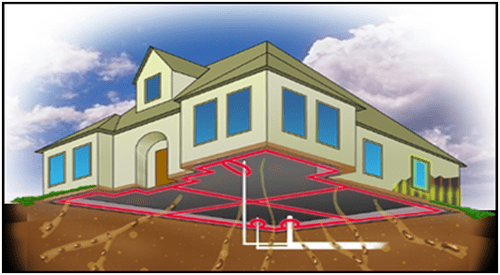

Termite Reticulation System is a contemporary method of termite treatment. A progressive work was planned successfully to keep away from termite passage in the structure. This most recent innovation is intended for Pre-construction Termite treatment, to adequately treat the construction before the flooring is finished. It includes lying of flexible, persistently perforated 16 mm pipe along the inside and the outside walls of the structure and center of the flooring with junction box attached. This perforated line permit uniform dispersion of termite emulsion under the flooring. These perforated tubes circulate at a pre-determined rate and decrease the danger of any area left untreated.

About Our Services

Who should use Reticulation System?

Termite Reticulation System can be used on a new building or one that’s undergoing renovations – such as an extension. A reticulation system is often a requirement for building owners wanting to build a termite-free building or who hate to lose a lot of wooden interiors by termite attack.

How did Reticulation System work?

Indian standard 6313 Part II stipulates that there has to be a rechargeable termite barrier between the foundation of constructions and under each poured concrete slab. In this case, we would lay a termite reticulation line underneath the slab where the slab meets the flooring, so that it’s rechargeable when the chemical meets the end of its life cycle. We connect it up and re-fill the line through the junction box installed. The termiticide goes in at a certain pressure, through the line, and disperses to form a termite-treated zone under the concrete slab.

Chitwan Multi Services Pvt.Ltd. offer Anti Termite Treatment Services and Termite Control Services to our clients for their homes, office, and other buildings. Continuous use of perforated porous pipes ensures no debris; clay or concrete will block the pipe, making it ineffective. The pipe structure pushes the substrate aside and prevents choking. Chemical emulsion in these porous pipes should be topped up every three years in order to maintain their effectiveness